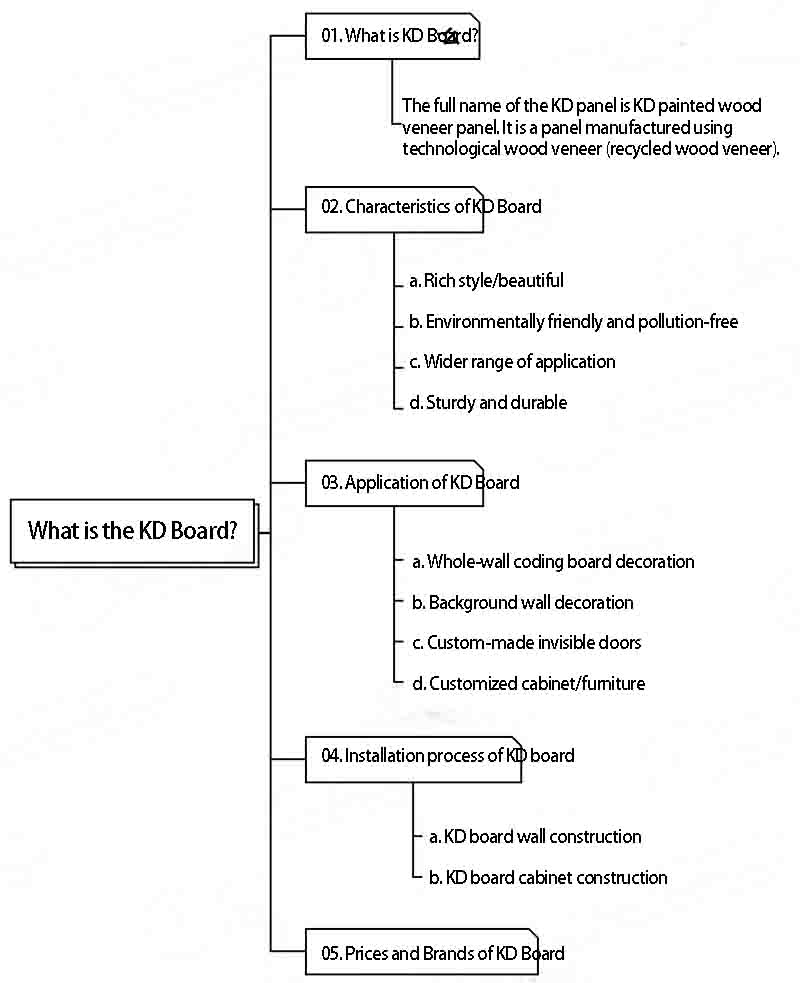

KD board is also known as KD board. It is a kind of painted wood veneer board made from thin veneer of solid wood + plywood. Its name originates from the Taiwan KD Company. Because the KD company was the first company to develop this wood veneer panel, it was named this material after KD board. Today we will introduce K Ding board from the following five aspects.

- What is KD board?

- Characteristics of KD Board

- Application of KD Board

- The installation process of KD board

- The price and brand of KD board

1. What is KD board?

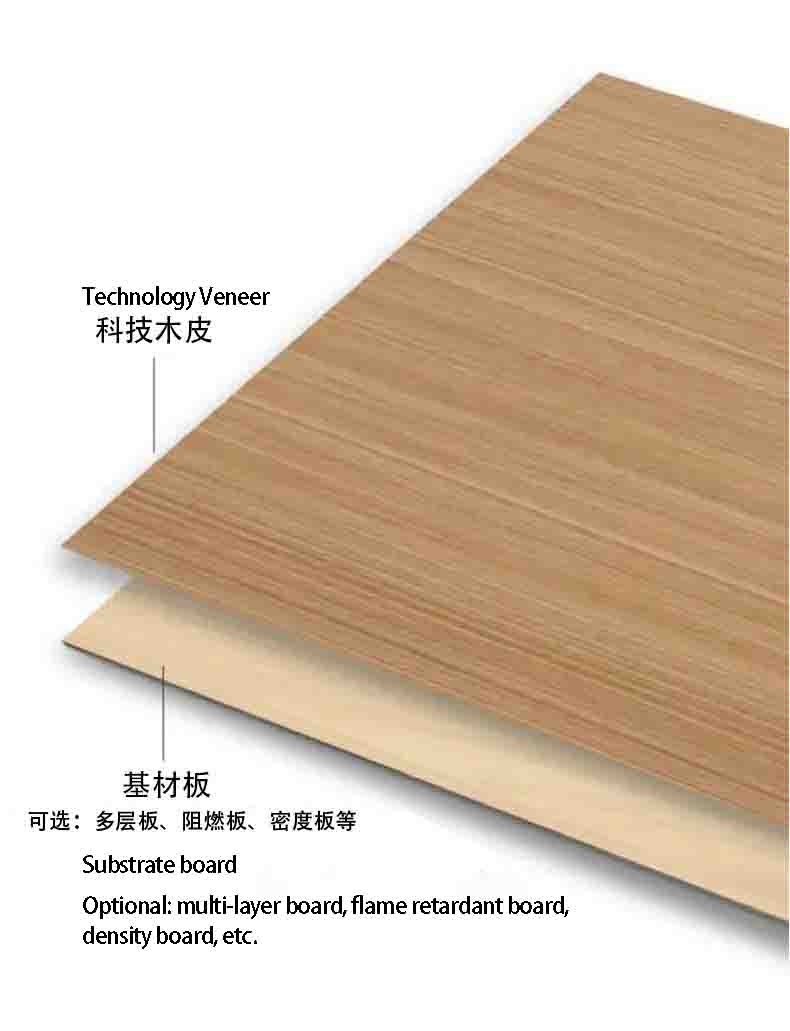

The full name of KD panel is KD painted wood veneer panel. It is a panel made of technical wood veneer (recycled wood veneer). The raw wood is used as the raw material, and after a series of design, staining, reconstructing, insect removal treatment, high temperature and pressure, it is produced into technology veneer. The veneer on the surface of the finished product has a very realistic feel and look of real wood, and is very classy.

The difference between the veneer and the veneer panel.

The difference between the two is the different materials used. The raw material used for veneer is more abundant than that of KD. It uses wood, stone, metal, etc. cut into thin slices. In the production process, the veneer is bonded and pressed, so the treatment between the two types of panels is also different. There is also a difference in price between the two. Generally, KD board is more expensive and more suitable for consumers of high-end decoration.

2. Characteristics of KD board

Rich style and beautiful.

There are many styles of solid wood veneer on the surface of KD board. The original wood veneer is rich in natural texture and three-dimensional texture level. The surface of solid wood veneer of KD board has a sense of concave and convex. Its feel is closer to the original wood grain, and the wood grain pattern is more natural.

Environmentally friendly and pollution-free.

The production site of KD Board is completely free of spray paint, so there is no dust pollution from spray paint and sanding. The plywood used in KD Board is in accordance with national standards. It is better than the E1 (old standard E0) national certification. Its formaldehyde emission is much lower than the national standard requirement. It is environmentally friendly and pollution-free, and can be used in interior design with confidence.

Wider scope of application.

KD board can provide various spellings, surface treatment and customized size according to design requirements. It is widely used in interior tops, wall cabinets, etc. It can not only make the whole room uniform in material and style, but also easily handle the installation of irregular surfaces such as curved shapes.

Sturdy and durable.

The use of penetrating water-based paint allows the best combination of paint and wood veneer. It has excellent adhesion. The paint surface protects the veneer and is relatively less susceptible to moisture. Its service life is more than double that of traditional methods.

Of course, there are also some disadvantages. For example, the price of KD board is more expensive. It is mainly the veneer panel made by the Taiwan brand Co. The raw material alone is more expensive. So although the decoration effect of the Koding board is good, but only for consumers with a higher level of decoration.

The installation process is more, KD itself is a veneer panel. It needs to be fixed to the base. This is one more process, and the maintenance is more troublesome.

3. Application of KD board

The application of KD board is very wide, it can be used in the whole wall customization, top decoration, custom cabinet, door panel, etc.

a.Whole wall decoration

The whole wall decorative KD board can play a role in protecting the wall and enhancing the aesthetic effect. It can be matched with the overall style, mostly applied to the minimalist style, Italian minimalist style, etc.

b.Background wall decoration

The back wall is the center of vision in interior design. A large area of KD board on the wall, modelling simple without losing style. Especially when there is a custom modeling, the use of KD board decoration effect is better.

c.Customized invisible door

When the wall modeling needs to incorporate the invisible door, use KD board to do the whole customization, not only does not affect the aesthetics, but also the door and the wall can be perfectly integrated.

d.Customized cabinet/furniture

When you need to customize a large area of woodwork at home, it is easy to have a mismatch of materials and textures. But using KD board customization can avoid this very well. It can use the same texture from the wall to the home, which perfectly solves the embarrassment caused by material differences.

The surface material of the furniture can also be made of KD board. After assembling the furniture shape using the base board, the finish is decorated.

4. The installation process of KD board

a. KD board wall construction

Construction steps: cut the board according to the size —- adhesive on the back of the board —- measure and mark the location of the paste —- cut the non-woven fabric according to the size —- paste the non-woven fabric —- attach the kedging board —- wall finish

Construction points.

①Cut the KD board according to the required size, then color the cut surface with corner paint and let it stand for 10 minutes, after which it will be pasted.

②The wall part is marked with tape measure and ink line device for pasting position, after completion, cut the non-woven fabric with hobby knife, paste the non-woven fabric on the wall and paste the non-woven fabric tightly with press board, then paste the cut K Ding board on the corresponding position on the wall, and gently tap with hammer and wooden block spacer, tear off the adhesive film on the K Ding board and finish the construction of the wall.

b.Construction of K Ding board cabinet

Construction steps: cut K Ding board according to the size —- K Ding board back cloth adhesive paste —- repair the edges to smooth —- cut non-woven fabric and brush glue —- non-woven fabric paste and trim the edges —- corner line paint —- cabinet finished

Construction points.

① must be the base of the cabinet assembly is completed after the Koding board in accordance with the required size for cutting. After the completion of cutting, the cabinet body will be ready to be laminated and the back of the board will be painted with strong adhesive. Then laminate the panel with the cabinet, and gently beat it with hammer and spacer to make the paste surface completely tightly combined.

② Use trimming knife to trim the excess board on the side and use sandpaper to smooth it out. Then the required paste cabinet at the back of the non-woven fabric with strong adhesive painting. After that, cut the required size with a hobby knife. Then paste the cut non-woven fabric on the side of the cabinet and paste it tightly with a press board. Cut off the excess non-woven fabric with a hobby knife. Sand with 240 and 400 grit sandpaper, followed by the corner line paint. Finally, after lightly sanding with 800-gauge sponge sandpaper, the cabinet is finished.

05.The price and brand of KD board

The standard size of KD board is 1220mmx2440mm, with thickness ranging from 5mm to 25mm. Its price varies from 200-400 yuan.

The last picture summarizes today’s content.

WOWOW Faucets

WOWOW Faucets

您好!Please sign in