In the intricate web of household plumbing, the toilet supply line often occupies a peripheral role. However, understanding its complexities, particularly the standard sizes, is crucial for maintaining a well-functioning and efficient bathroom. What is the standard toilet supply line size? This comprehensive guide delves into the nuances of the standard toilet supply line size, exploring dimensions, the myriad factors influencing size selection, and the intricacies of installation.

Unraveling Standard Sizes:

Toilet supply lines predominantly come in two standard sizes: 3/8 inch and 1/2 inch. These measurements refer to the diameter of the threaded end connecting to the toilet tank, with the opposite end linking to the water supply valve. The choice between these sizes involves a careful consideration of multiple factors, each playing a pivotal role in the overall performance of your toilet.

Factors Shaping Size Selection:

- Water Pressure Dynamics:The relationship between water pressure and supply line size is critical. High water pressure scenarios may necessitate a larger diameter to facilitate optimal water flow, ensuring efficient toilet operation. Conversely, lower water pressure areas might find a smaller supply line sufficient.

- Flow Rate Requirements:Flow rate, intimately tied to size, directly impacts the efficiency of flushing and tank refilling. Opting for a larger diameter allows for a higher flow rate, catering to households with increased water demands. Carefully assess your specific requirements to make an informed choice.

- Local Plumbing Codes:Plumbing regulations vary across regions, underscoring the importance of adherence to local codes. Understanding and complying with these codes ensures not only the correct supply line size but also promotes standardized practices and safety within your plumbing system.

Installation Considerations Explored:

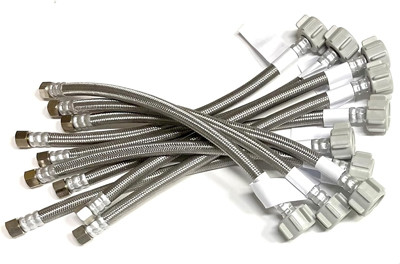

- Material Durability:The choice between braided stainless steel and reinforced plastic hinges on durability and environmental considerations. Stainless steel offers corrosion resistance, while reinforced plastic provides flexibility. Tailor your choice to the demands of your plumbing setup.

- Optimal Length Requirements:Supply lines are available in various lengths to accommodate diverse toilet and water supply valve placements. Precise measurement of the distance between the valve and the toilet tank is paramount to selecting an appropriate length, preventing undue stress on the line.

- Connection Types:Supply lines typically feature either compression or threaded connections. The former facilitates tool-free installation, while the latter may require wrenches for a secure fit. Choose a connection type aligned with your installation preferences and expertise.

- Flexibility vs. Rigidity:The flexibility of the supply line becomes a crucial consideration during installation. Flexible lines, easy to install and adjustable, contrast with rigid lines offering stability and a more fixed configuration. Assess your installation requirements to determine the optimal choice.

- Shut-Off Valve Compatibility:Ensure compatibility between the toilet supply line and the shut-off valve. Upgrading the supply line may require replacing the shut-off valve to maintain optimal performance, emphasizing the interconnected nature of these plumbing components.

The Importance of Water Pressure:

Water pressure is a cornerstone consideration when selecting the size of your toilet supply line. Understanding the dynamics of water pressure in your plumbing system is essential for ensuring that your toilet functions efficiently. In areas with high water pressure, a larger supply line may be necessary to accommodate the increased water flow required for effective flushing and tank refilling. Conversely, in regions with lower water pressure, a smaller supply line may be sufficient, as it can provide the necessary flow without overtaxing the plumbing system.

Flow Rate and Its Impact on Performance:

Flow rate, closely tied to the size of the supply line, is a critical factor influencing the overall performance of your toilet. Flow rate refers to the volume of water that can pass through the supply line in a given amount of time. Choosing a larger diameter supply line allows for a higher flow rate, ensuring that the toilet tank can quickly refill after flushing. This not only enhances the efficiency of the toilet but also contributes to water conservation by reducing the time it takes for the tank to replenish.

Considering Local Plumbing Codes:

Plumbing codes and regulations are put in place to ensure the safety and standardization of plumbing systems. These codes may vary from one location to another, and it’s essential to familiarize yourself with the specific requirements in your area. Local plumbing codes may dictate the acceptable sizes and materials for toilet supply lines, aiming to create uniformity and prevent issues that could compromise the integrity of the plumbing system. Before embarking on a toilet supply line installation or replacement project, check with local authorities or consult a plumbing professional to ensure compliance with relevant codes.

Material Matters: Stainless Steel vs. Reinforced Plastic

The material of the toilet supply line is a crucial consideration, impacting both durability and flexibility. Two common materials used for toilet supply lines are braided stainless steel and reinforced plastic, each offering distinct advantages.

- Braided Stainless Steel:

- Durability: Stainless steel is known for its durability and resistance to corrosion. Choosing a braided stainless steel supply line ensures a long lifespan and minimizes the risk of leaks or deterioration over time.

- Stability: Stainless steel provides stability, which is particularly beneficial in scenarios where the supply line may be exposed to external forces or movement.

- Reinforced Plastic:

- Flexibility: Reinforced plastic supply lines are flexible, making them easier to install and adjust. This flexibility is advantageous when dealing with tight spaces or when minor adjustments are needed during installation.

- Corrosion Resistance: While not as corrosion-resistant as stainless steel, reinforced plastic still offers reasonable resistance to corrosion, especially when compared to traditional metal supply lines.

Choosing between these materials depends on your specific needs, the environmental conditions of your plumbing setup, and considerations such as the stability required and the ease of installation.

Optimal Length Requirements:

The length of the toilet supply line is a crucial factor that directly impacts the ease of installation and the overall performance of the plumbing system. Supply lines are available in various lengths to accommodate different toilet and water supply valve placements. Before purchasing a supply line, measure the distance between the water supply valve and the toilet tank to ensure that you select an appropriate length. An excessively long or short supply line can lead to installation challenges or place unnecessary stress on the line, potentially causing leaks or other issues over time.

Connection Types: Compression vs. Threaded

The type of connection used in a toilet supply line is an important consideration, as it can impact the ease of installation and the security of the connection. Toilet supply lines typically feature either compression or threaded connections, each with its own set of advantages.

- Compression Connections:

- Tool-Free Installation: One of the primary advantages of compression connections is that they allow for tool-free installation. This can be particularly convenient for homeowners who prefer a DIY approach to plumbing projects.

- Easy Adjustment: Compression connections are often more forgiving when it comes to adjustments. If minor tweaks are needed during installation, compression connections can accommodate these changes without requiring additional tools.

- Threaded Connections:

- Secure Fit: Threaded connections, secured with nuts and threaded ends, provide a secure and stable fit. This can be advantageous in situations where a robust and steadfast connection is essential.

- Wrench Required: Unlike compression connections, threaded connections typically require the use of a wrench for proper tightening. This ensures a snug fit and minimizes the risk of leaks.

When choosing between compression and threaded connections, consider your comfort level with plumbing installations, the tools you have available, and the specific requirements of your setup.

Flexibility vs. Rigidity: Finding the Right Balance

The flexibility of the toilet supply line is a key consideration during installation. The degree of flexibility needed depends on factors such as the layout of your plumbing system, the space available for installation, and any potential obstacles that may be encountered.

- Flexible Supply Lines:

- Easy Installation: Flexible supply lines are generally easier to install, especially in scenarios where space is limited or awkward angles need to be navigated. The flexibility of these lines allows for easier maneuvering during the installation process.

- Adjustability: The flexibility of the supply line also provides a degree of adjustability. This can be beneficial when making minor adjustments to ensure a proper fit.

- Rigid Supply Lines:

- Stability: Rigid supply lines offer stability and a more fixed configuration. Once installed, they are less prone to movement or shifting, providing a stable connection between the toilet tank and the water supply valve.

- Durability: While less flexible than their counterparts, rigid supply lines can be durable and resistant to wear and tear over time.

The choice between flexible and rigid supply lines depends on the specifics of your installation. If navigating tight spaces or making adjustments is a concern, flexible supply lines may be the preferred option. On the other hand, if stability and a more fixed configuration are paramount, rigid supply lines may be the better choice.

Shut-Off Valve Compatibility:

The shut-off valve is a critical component of the plumbing system, allowing for the isolation of water flow to specific fixtures or appliances. When upgrading or replacing a toilet supply line, it’s important to ensure compatibility with the existing shut-off valve. In some cases, the installation of a new supply line may necessitate the replacement of the shut-off valve to maintain optimal performance.

- Compatibility Checks:

- Before purchasing a new toilet supply line, check the type and size of the existing shut-off valve. Ensure that the new supply line has the correct connection type and diameter to seamlessly attach to the shut-off valve.

- If the shut-off valve is outdated or shows signs of wear, it may be advisable to replace it concurrently with the installation of a new supply line. This proactive approach can prevent potential issues down the line and contribute to the overall reliability of the plumbing system.

Conclusion:

In the intricate tapestry of household plumbing, the toilet supply line emerges as a silent hero, facilitating the daily rhythm of life. A nuanced understanding of standard sizes, coupled with considerations such as water pressure, flow rate, and local regulations during installation, empowers homeowners to make informed decisions. Your choice in toilet supply line size, seemingly minor, contributes significantly to the efficiency and reliability of your bathroom experience, marking a small yet impactful step towards a seamlessly functioning plumbing system.

Whether you opt for the durability of braided stainless steel or the flexibility of reinforced plastic, whether you choose compression for its tool-free ease or threaded for a secure fit, each decision plays a role in the overall performance of your toilet. The compatibility with the shut-off valve, the optimal length, and the balance between flexibility and rigidity further enhance the installation process.

In the grand scheme of home maintenance, the toilet supply line may be a humble component, but its significance is undeniable. As you navigate the depths of toilet supply lines, armed with the knowledge of standard sizes and installation considerations, you contribute not only to the functionality of your bathroom but also to the overall harmony of your home. With each thoughtful choice, you pave the way for a plumbing system that works seamlessly, ensuring that the unsung hero, the toilet supply line, continues to play its vital role in the background of your daily life.

WOWOW Faucets

WOWOW Faucets

您好!Please sign in